LED electronic displays are widely used in our lives. Maybe everyone has a simple understanding of LED electronic displays, but is it really deeper? Today, Xiaobian conducted conceptual clarification and discussion on several common misunderstandings of Huidu LED electronic displays.

LED electronic display software is not : freecurrently only a few companies have genuine software. It is now illegal to use piracy.

Point-by-point correction does not require the use of a dedicated driver chip: as long as the control system supports it, a general-purpose driver chip can also achieve point-by-point correction!

Chromaticity correction is not equal to chromaticity uniformity correction. The application of chromaticity correction is more the conversion of gamut space. Under normal circumstances, after brightness correction, the brightness uniformity of the display can reach a very high level, plus color space correction, the color fidelity of the display can also reach a very high level. Chroma correction and chroma uniformity correction.

- Chroma correction: To meet the customer’s special requirements for the display color gamut space: Correct the display color gamut space to the customer-specified color space. Improve the color fidelity of the display and make the color reproduction more real: Correct the color gamut of the display to standard color spaces such as SRGB and NTSC.

- Chromatic Uniformity Correction: Due to the good accuracy and stability of the color separation and color separation machine, and the effective process of mixing lamps and crystals, the application of chromaticity uniformity correction is quite limited. It must be used when cleaning inventory Mix very small and scattered wavelength lamps on one screen. At this time, chromaticity uniformity correction is also the only option. Due to errors in the professional production process, lamps / chips of different wavelengths were mixed together and used on the same screen. Chroma uniformity correction can be used as a last resort.

- Point-by-point correction: Point by point correction is not done by the control system manufacturer. The calibration technology is not bundled with the control system. The real necessary conditions for point-by-point correction are.

A Control System Capable Of Achieving Point-By-Point Correction

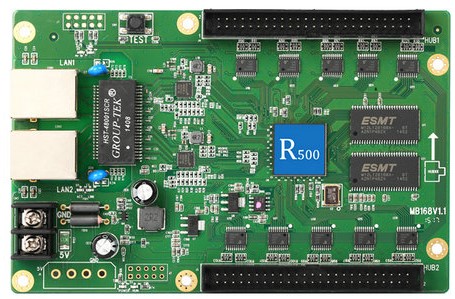

High-precision, high-efficiency light point brightness collection equipment. Summary: Point-by-point drive control has long been implemented, and universal control systems on the market already have this function. However, for the collection of millions of lamp point data in LED control card, some control system manufacturers have developed various tools, and these collection methods are incompatible with other systems. As a result, point-by-point correction and control systems are bundled and integrated into a misunderstanding.

Gray scale of LED electronic display

Grayscale as a dual-primary and full-color display is an important indicator. At present, the market is flooded with many 16-level and 64-level grayscale displays posing as 256-level grayscale. Its control cost is only 1/5 of the 256-level grayscale control. The easiest way is to play LED a VCD of a more intense sports scene to see if it can be clearly seen on the LED electronic display.